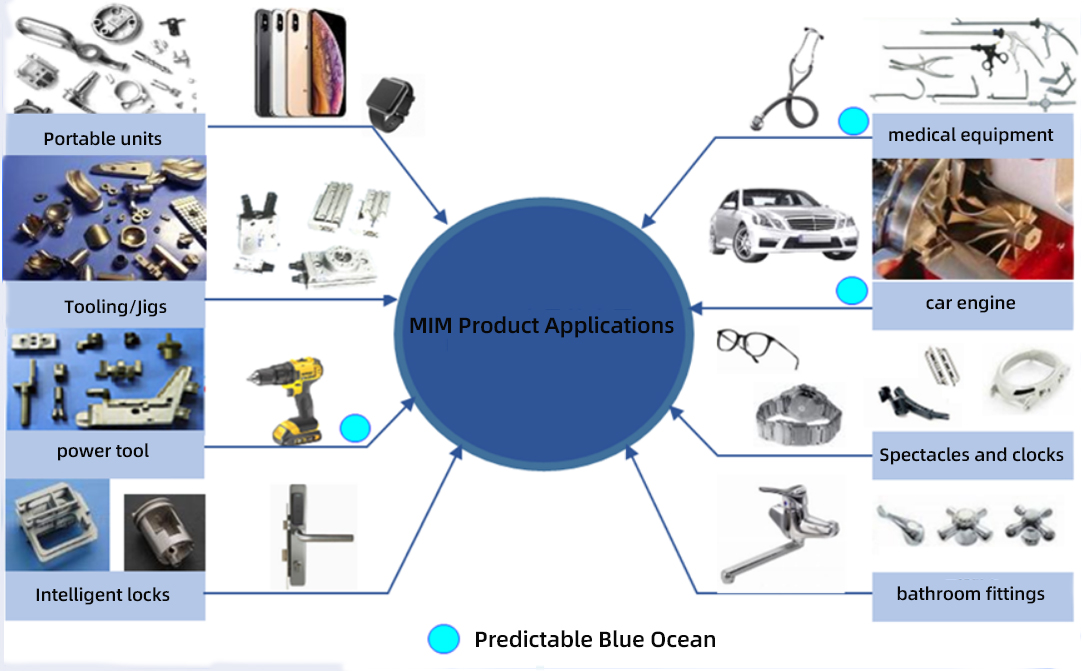

MIM is used in a wide range of applications such as consumer electronics, automotive parts, medical devices, power tools, industrial equipment, and everyday products.

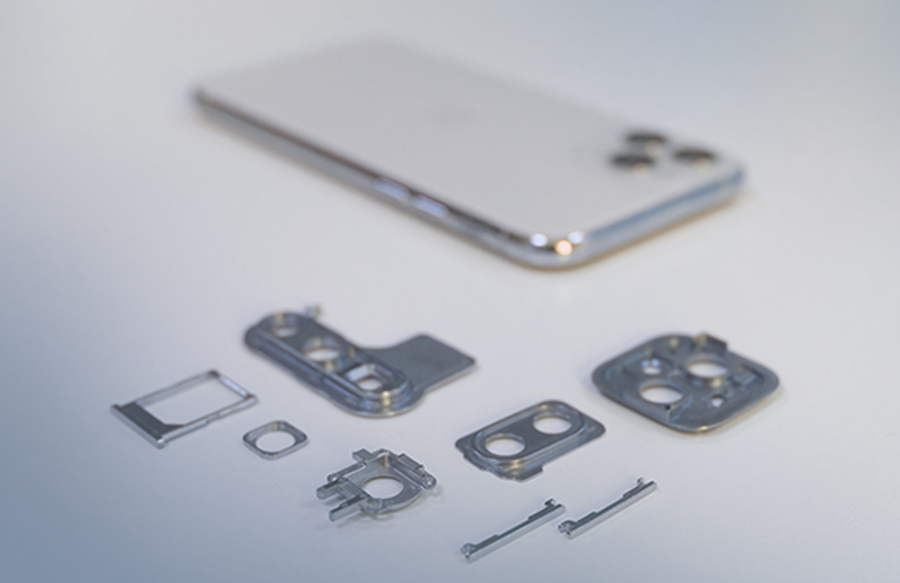

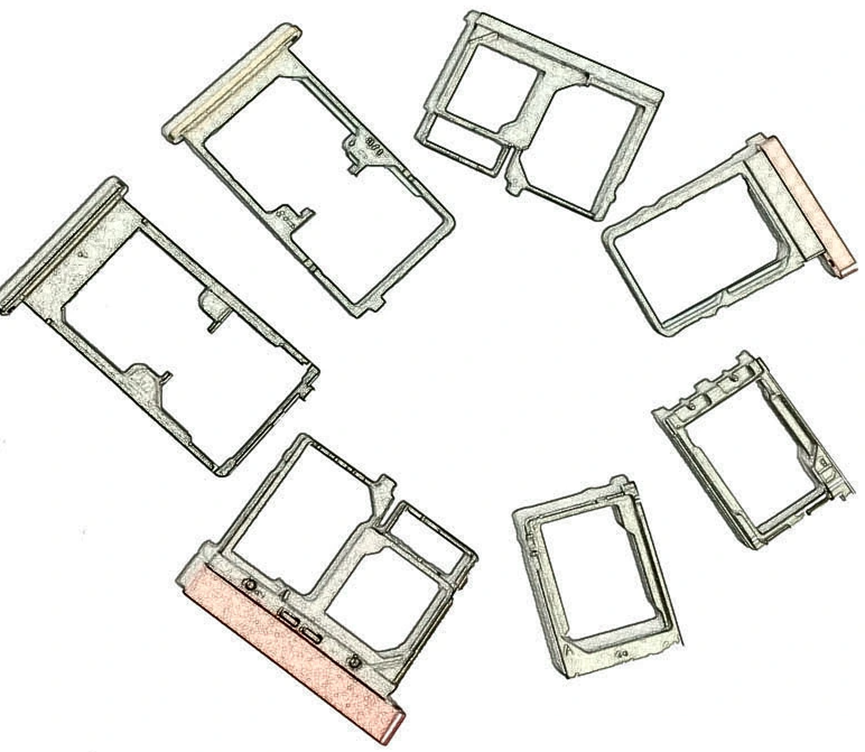

1, consumer electronics field

Consumer electronics products usually include smart phones, tablet PCs, laptops, digital cameras, smart wearable devices, unmanned aircraft and so on.

In 2010, BlackBerry's signage appearance parts using MIM process technology, opened the MIM parts in the cell phone on the bulk use.

Apple has also started to use MIM parts since 2010, and continues to expand and lead the use of MIM, power connector, brackets, hinges, camera rings, buttons and other MIM parts in the cell phone have achieved successful application.

With the development of smart phones, smart wearable devices and other consumer electronics products to more thin and light, the core components of these products will be more precise and complex. In this context, the application prospect of MIM technology will be increasingly broad.

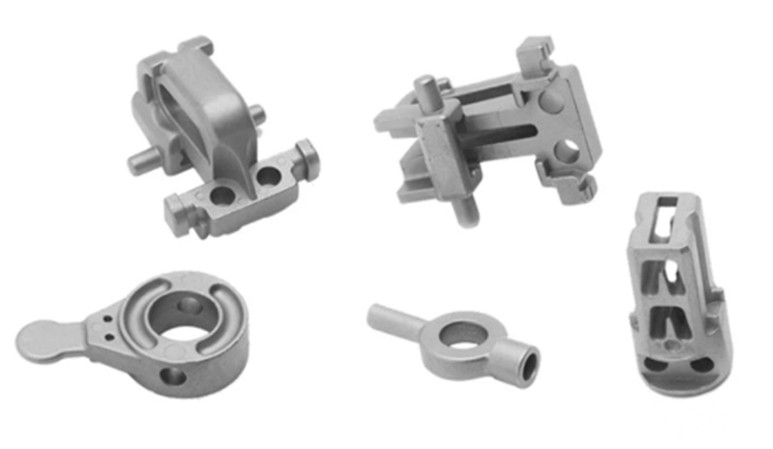

2, automotive parts

In the field of automotive parts manufacturing, MIM process as a non-cutting metal parts molding process, can save materials, reduce production costs, so the MIM process by the automotive industry attaches great importance to, and in the 1990s began to be used in the automotive parts market.

At present, the automotive industry has used MIM process to produce some complex shapes, bimetallic parts and groups of micro-small parts, such as turbo parts, adjusting rings, injector parts, blades, gearboxes, power steering components and so on.

3, medical equipment

In the field of medical equipment, MIM process production of medical parts with high precision, to meet the majority of precision medical equipment on the parts needed for small, high complexity, high mechanical properties and other requirements.

In recent years, MIM process has been more and more widely used, such as scalpel handle, scissors, tweezers, dental parts, orthopedic joint parts.

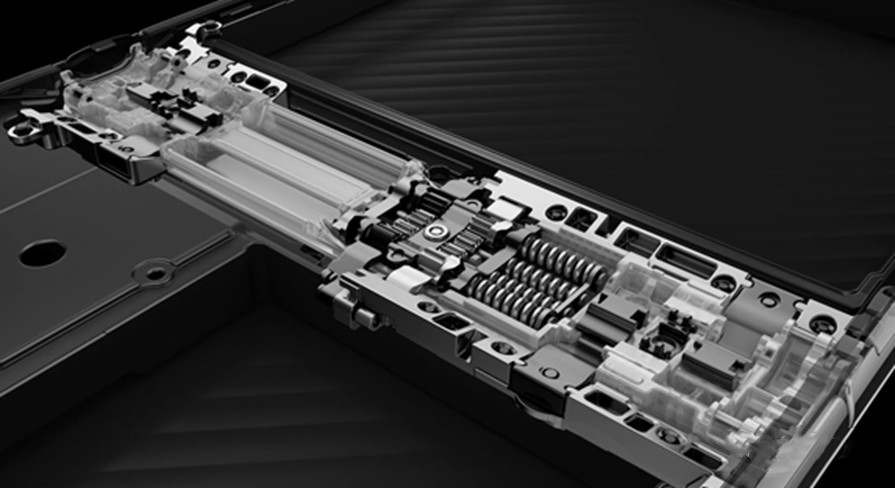

4 Power tools

The machining of power tool parts is more complex, higher processing costs, low material utilization, more dependent on MIM, typical products include shaped milling cutters, cutting tools, fasteners, micro gears, cotton loosening machine / textile machine / crimping machine parts, etc. developed in recent years.

ipcode:

ipcode: